Standard Testing:

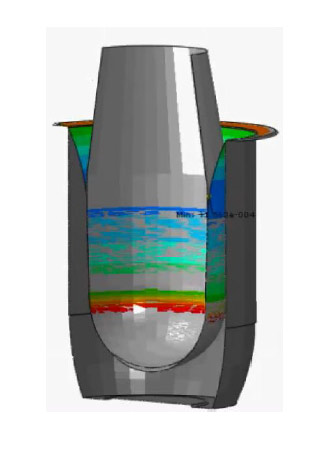

At Pack 3.0 we virtually test your package to ensure compliance with FEA standards (ASTM or ISTA protocol) such as:

- Top-load (ASTM E898) – empty or filled container

- Drop testing (ASTM D2463)

- Impact (ASTM D3029, ASTM D1822)

- Pressure resistance (ASTM D4919)

- Vacuum (ASTM D4991)

- Sidewall tensile strength (ASTM D638)

- Burst pressure (ASTM F1140, FEA 647 F)

- Vibrations (ASTM D4728)

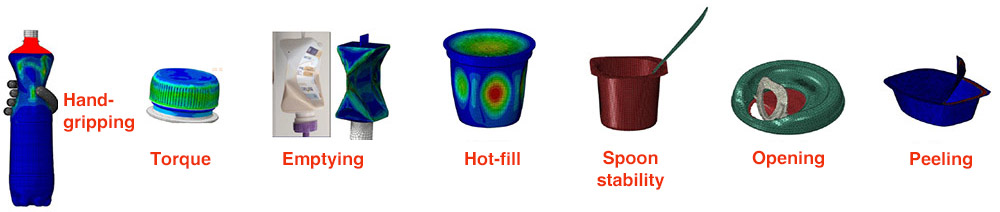

Custom Testing:

Not satisfied with only standardized tests? Pack 3.0 helps you develop customized tests that are most relevant for your packaging requirements. These would include:

- Peeling

- Hand-gripping

- Spoon stability

- Torque

- Emptying

Design verification and improvement

Make sure your package works correctly for consumers and can survive the stresses put on it at every stage of its lifecycle, from production to shipping to consumption.

Material costs and savings

We investigate opportunities to make your packaging lighter and discover how to reduce or improve the materials you use.

CO2 reduction

We can discover possibilities to help you cut waste, reduce energy requirements and use more environmentally-friendly materials.

Reduce risks and prevent damages

With digital simulation, we can subject your packaging to a vast range of real world tests to guarantee they’ll function properly and stand up to the rigors found at all stages of the product’s lifecycle.

Troubleshooting

Have a problem with a package design or a troublesome question? We love to discover new solutions. Let’s work together and find the answers.

Improve consumer experience

Ensure your customers’ happiness by maximizing a product’s appearance, ergonomics, ease of use and functionality.

Thanks to our scientific background and connections with the top-level universities or research institutes involved in packaging materials science or digital simulation technology, Pack 3.0 can develop new simulation models related to:

- New packaging materials such as bio-based plastics (PEF, PLA) and reinforced polymers

- New packaging processes

- New testing protocols

- New packaging solutions such as plastic aerosol

Pack 3.0 is currently leading a 3-years PHD program to develop a new digital simulation approach for thermoforming process in partnership with the University of Reims, Champagne-Ardenne, France.

Pack 3.0 is part of a multi-national collaboration that aims to develop “A novel instrument for characterization of pre-forms and bottles for injection stretch blow molding”. (Program called INDICATE, 3 years research project, 1M€ funding).